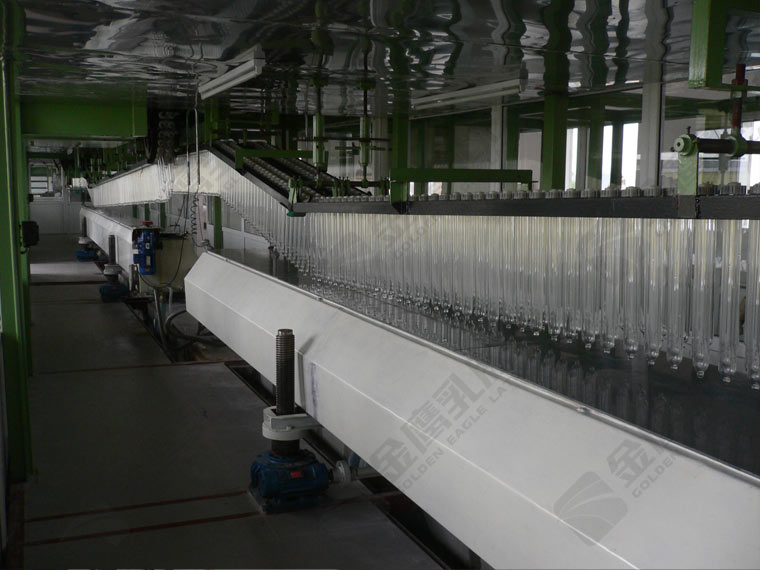

Technical parameter

Shape dimension(L×W×H): 65m×3m×4.5m

Main Motor transmission: 2.2KW×3Set

Thermal energy consumption(Steam): 1T/h

Power consumption: 70KW

Water consumption: 6T/h

Chain length of production line: 215m

Mould space: 80mm

Chain linear velocity: 0~10m/minute

Quantity of moulds: 5,400 pcs

Productivity: 350,000pcs/24h

Soft water: 10T/24h

Technical characteristics

1. Adopt advanced three-time latex dipping technology, advanced process layout and diversified adjustment of production technology.

2. Cancel the ammonia wate swelling process, which is changed to extended alkaline tank design. Reach the effect of swelling and leaching, environmental protection and saving.

3. Templates are fabricated with SS304 plate. The whole chain is driven by three sets of main motors, with varying frequency speed control system. The equipments are running smoothly and steadily.

4. The whole machine is equipped with stainless steel plates in the ceiling, and sealed with plastic steel.

5. The equipment is designed fully, effectively, reliably and reasonably to prevent the condom from bubble head, flow reversals, wryneck, curling, pinholes etc.

6. Can produce different kinds of common and irregular-shaped condoms with shiny side, granule, thread and multicolor.

7. Adopt the fully-enclosed stainless steel tubes to pressure convey the latex material in production.

8. Energy saving design in drying structure, with consumption of 19.5kgs of standard coal per 10,000 condoms.

9. Clean Water stripping, continuous acid washing, fully ensure the moulds and equipmemt clean.

10. Mixing powder on machine, dehydration and direct drying in post vulcanization makes the production operation more energy saving and simple.

Related equipment